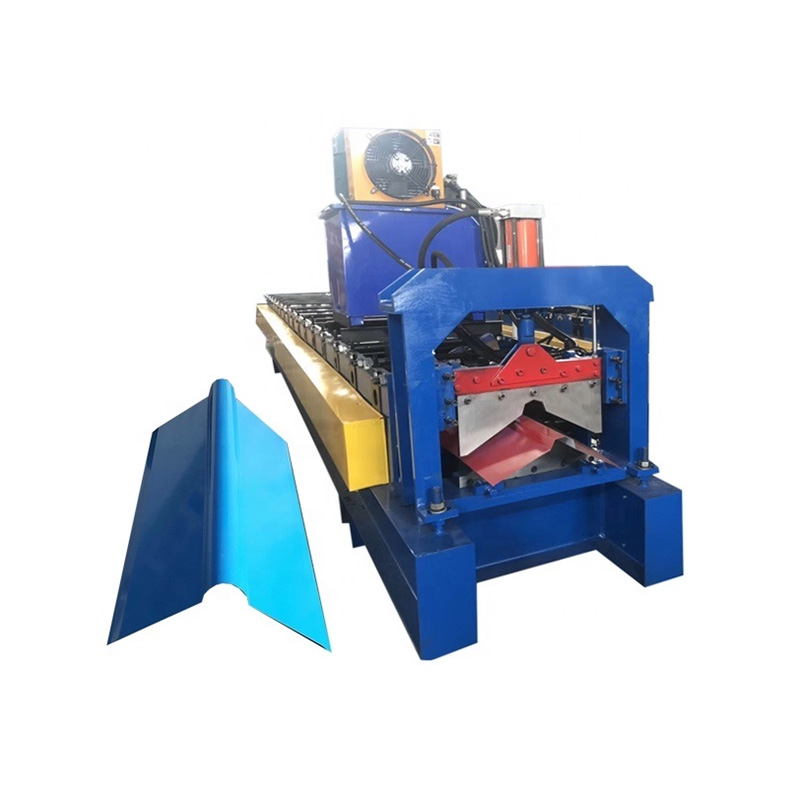

High-Quality Metal Roof Roll Forming Machine for Sale

By:Admin

The roofing industry has seen a technological revolution in recent years, and the introduction of the Roof Roll Forming Machine from (remove brand name) is a game-changer. This innovative machine has the capability to dramatically improve the efficiency and quality of roof installation, making it a vital tool for roofing companies looking to stay ahead in a competitive market.

The Roof Roll Forming Machine is a state-of-the-art piece of equipment that is designed to efficiently produce metal roofing panels at a high speed. By utilizing advanced roll forming technology, this machine can accurately and precisely shape metal sheets into roofing panels of various designs and sizes. This enables roofing companies to meet the diverse needs of their clients while streamlining their production process.

One of the key features of the Roof Roll Forming Machine is its ability to produce roofing panels with consistent quality. Traditional methods of roof panel production often result in variations in the shape and size of the panels, leading to potential installation issues and aesthetic inconsistencies. With the Roof Roll Forming Machine, these concerns are a thing of the past. The machine's precision engineering ensures that each panel meets exact specifications, guaranteeing a uniform and professional finish for every roof installation.

In addition to its superior quality, the Roof Roll Forming Machine also offers a significant boost in efficiency for roofing companies. By automating the panel production process, this machine can produce a high volume of roofing panels in a short amount of time, reducing labor costs and increasing productivity. This means that roofing companies can take on more projects and meet tight deadlines without compromising on the quality of their work.

Furthermore, the Roof Roll Forming Machine is designed with user-friendly features that make it easy to operate and maintain. Its intuitive control system and simple setup process ensure that operators can quickly start using the machine with minimal training. Additionally, the machine's durable construction and reliable performance minimize the need for repairs and downtime, allowing for uninterrupted production and maximum return on investment.

As a leading manufacturer of roll forming equipment, (remove brand name) has a proven track record of delivering high-quality and innovative solutions to the construction industry. The company's commitment to research and development has resulted in the creation of the Roof Roll Forming Machine, which represents a significant advancement in roofing technology. With a focus on precision, efficiency, and user-friendliness, this machine is set to revolutionize the way roofing panels are produced and installed.

By investing in the Roof Roll Forming Machine, roofing companies can take their business to the next level and set themselves apart from the competition. With its ability to produce high-quality panels at a rapid pace, this machine offers a competitive edge that is essential in today's fast-paced construction market. The Roof Roll Forming Machine is not just a piece of equipment; it is a game-changer that has the potential to transform the roofing industry as we know it.

Company News & Blog

High-Quality Sheet Metal Roll Forming Machines: A Complete Guide

Sheet metal roll forming machines are a crucial piece of equipment in the manufacturing industry, especially in the production of custom metal parts for various industries. These machines are used to create complex shapes and patterns in sheet metal, providing greater efficiency and precision in the production process.Company X is a leading manufacturer of sheet metal roll forming machines, with a strong reputation for producing high-quality and reliable equipment. With a commitment to innovation and customer satisfaction, Company X's machines are trusted by manufacturers around the world to meet their specific production needs.The roll forming process involves passing a sheet of metal through a series of rollers to gradually shape the metal into the desired profile. This process is highly efficient and allows for the mass production of complex metal parts with consistent quality. Sheet metal roll forming machines from Company X are designed to be versatile, allowing for the production of a wide range of profiles and shapes, from simple bends to intricate designs.One of the key benefits of using Company X's sheet metal roll forming machines is the ability to create custom parts with minimal material waste. By precisely shaping the metal to the desired specifications, manufacturers can maximize the use of raw materials and reduce production costs. This also contributes to a more sustainable manufacturing process, as it minimizes the environmental impact of material wastage.In addition to their efficiency, Company X's sheet metal roll forming machines are also known for their durability and reliability. Built with high-quality materials and components, these machines are designed to withstand the rigors of continuous use in a manufacturing environment. This ensures that manufacturers can rely on their equipment to consistently produce high-quality parts without the need for frequent maintenance or repairs.Furthermore, Company X offers a range of customization options for their sheet metal roll forming machines, allowing manufacturers to tailor the equipment to their specific production requirements. Whether it's adjusting the speed and feed rates or adding specialized tooling, Company X works closely with their customers to ensure that the machines meet their unique needs. This commitment to customization further demonstrates Company X's dedication to providing comprehensive solutions for their clients.As the demand for custom metal parts continues to grow across various industries, the reliance on efficient and precise manufacturing equipment like sheet metal roll forming machines has become increasingly important. Company X's machines play a vital role in enabling manufacturers to meet this demand by providing the capabilities for mass production of custom metal parts with the highest level of precision.In conclusion, Company X's sheet metal roll forming machines are a cornerstone of the manufacturing industry, offering unparalleled efficiency, precision, and customization options for the production of custom metal parts. With a strong commitment to innovation and customer satisfaction, Company X continues to be a trusted partner for manufacturers around the world, delivering reliable and high-quality equipment to meet their specific production needs.

Ultimate Guide to Sandwich Roofing Sheet: Types, Benefits, and Installation

Sandwich Roofing Sheet Technology Revolutionizes the Construction IndustryThe construction industry is constantly evolving with new technologies and materials that improve building efficiency, durability, and sustainability. One of the most exciting innovations in recent years is the development of Sandwich Roofing Sheet technology. This revolutionary material has been making waves in the construction industry for its numerous benefits and applications.{Company Name} is at the forefront of this technological breakthrough, leading the way in manufacturing high-quality Sandwich Roofing Sheets for various construction projects. With decades of experience in the industry, {Company Name} is committed to providing innovative and sustainable solutions for the construction sector.Sandwich Roofing Sheets are composed of three layers: two outer layers of thin metal sheets and an inner insulating core, usually made of polyurethane foam, mineral wool, or expanded polystyrene. This unique design allows for superior insulation properties, exceptional strength, and resistance to harsh weather conditions.One of the key advantages of Sandwich Roofing Sheets is their thermal performance. The insulating core provides excellent thermal resistance, effectively regulating the indoor temperature of buildings and reducing the reliance on heating and cooling systems. As a result, Sandwich Roofing Sheets contribute to energy savings and overall environmental sustainability.Moreover, the durable and robust nature of Sandwich Roofing Sheets makes them ideal for various construction applications. Whether it's for commercial, industrial, or residential buildings, {Company Name}'s Sandwich Roofing Sheets offer long-lasting protection against moisture, wind, and impact. This ensures that the buildings are not only aesthetically pleasing but also structurally sound.Additionally, Sandwich Roofing Sheets are lightweight, which simplifies the installation process and reduces the overall load on the building's structure. This can lead to cost savings in construction and maintenance, making Sandwich Roofing Sheets a cost-effective choice for builders and developers.{Company Name} understands the importance of sustainability in construction, which is why they have developed Sandwich Roofing Sheets that are 100% recyclable. This commitment to environmental responsibility aligns with the growing demand for eco-friendly building materials and practices.In addition to their practical and environmental benefits, {Company Name}'s Sandwich Roofing Sheets also offer versatility in design. With a wide range of colors, finishes, and profiles available, builders and architects can customize the aesthetic appearance of buildings to suit their specific requirements.As the demand for energy-efficient and sustainable construction materials continues to rise, Sandwich Roofing Sheets have quickly gained traction in the market. They have become the material of choice for many construction projects, from commercial warehouses and industrial facilities to residential developments and agricultural buildings.With {Company Name} leading the way in manufacturing high-quality Sandwich Roofing Sheets, builders and developers can rely on their expertise and commitment to delivering innovative and sustainable solutions for the construction industry. The company's dedication to research and development ensures that their products remain at the forefront of technological advancements, meeting the evolving needs of the construction sector.In conclusion, Sandwich Roofing Sheets have revolutionized the construction industry with their exceptional thermal performance, durability, sustainability, and design versatility. {Company Name} continues to be a driving force behind this innovative technology, providing builders and developers with a reliable and sustainable solution for their construction projects. As the industry continues to embrace energy-efficient and eco-friendly materials, Sandwich Roofing Sheets are poised to play a significant role in shaping the future of construction.

Durable and Insulated Sandwich Panels for Construction Projects

Pir Sandwich Panel: The Future of Sustainable Building ConstructionIn today's fast-paced world, the construction industry is always looking for innovative solutions that not only make the building process more efficient but also promote sustainability. Pir Sandwich Panel, a cutting-edge building material, is paving the way for the future of sustainable construction.[Company Name], a pioneer in the construction and building materials industry, is at the forefront of promoting the use of Pir Sandwich Panel. With a strong commitment to environmentally friendly practices and a focus on innovation, [Company Name] is leading the way in revolutionizing the construction industry.Pir Sandwich Panel is a high-performance building material that consists of two layers of metal with a polyisocyanurate (PIR) foam core. This combination results in a lightweight, durable, and highly insulated panel that offers numerous benefits for the construction industry.One of the key advantages of Pir Sandwich Panel is its exceptional thermal performance. The PIR foam core provides outstanding thermal insulation, which helps to reduce energy consumption and lower heating and cooling costs for buildings. This energy-efficient quality makes Pir Sandwich Panel an ideal choice for sustainable construction projects, aligning with [Company Name]'s commitment to environmental responsibility.Additionally, Pir Sandwich Panel offers excellent fire resistance, making it a safe and reliable choice for building construction. Its high strength-to-weight ratio also contributes to its structural integrity, providing durability and longevity for buildings constructed with this innovative material.Furthermore, Pir Sandwich Panel is incredibly versatile and easy to install, streamlining the construction process and reducing labor costs. Its lightweight nature makes it easier to handle and transport, leading to faster construction times and improved efficiency on building sites. This aligns with [Company Name]'s dedication to enhancing the construction process and delivering exceptional results for their clients.Another key benefit of Pir Sandwich Panel is its design flexibility. The panels can be customized to meet specific architectural and aesthetic requirements, allowing for endless design possibilities in both commercial and residential construction projects. This versatility positions Pir Sandwich Panel as a top choice for architects, builders, and developers seeking to create sustainable, modern, and visually striking buildings.[Company Name] is dedicated to promoting the use of Pir Sandwich Panel as part of its mission to advance sustainable construction practices. With a focus on research and development, [Company Name] continues to explore new and innovative ways to maximize the potential of this groundbreaking material, pushing the boundaries of what is possible in sustainable building construction.The use of Pir Sandwich Panel is also in line with [Company Name]'s commitment to reducing the environmental impact of construction. By promoting energy-efficient and sustainable building materials, the company is contributing to a greener, more environmentally conscious future for the construction industry.As the demand for sustainable building solutions continues to grow, Pir Sandwich Panel is poised to play a significant role in shaping the future of construction. With [Company Name] leading the way in advocating for the use of this innovative material, the industry is set to embrace a new era of sustainable, efficient, and visually captivating building construction.

Durable Stainless Steel Coil for Various Applications

{Company Name}, a leading manufacturer and supplier of stainless steel products, has launched a new stainless steel coil that is set to revolutionize the industry. The company, with its extensive experience and state-of-the-art facilities, has gained a reputation for producing high-quality stainless steel products, and the new stainless steel coil is no exception.The stainless steel coil, which is available in various grades and finishes, is designed to meet the diverse needs of the market. Whether it is for industrial, architectural, or decorative purposes, {Company Name} has ensured that its stainless steel coil is capable of delivering exceptional performance and aesthetics. With its superior corrosion resistance, strength, and durability, the stainless steel coil is suitable for a wide range of applications, including roofing, cladding, and fabrication.One of the key features of the new stainless steel coil is its versatility. It can be easily formed, cut, and welded, making it an ideal choice for complex and customized designs. Additionally, the coil is available in different widths and thicknesses, allowing customers to select the most suitable option for their specific requirements.In terms of surface finish, {Company Name} offers a variety of options, including polished, brushed, and etched finishes. This provides customers with the flexibility to choose the most suitable look for their projects, whether it is for a modern, sleek appearance or a textured, rustic finish.{Company Name} has always been committed to delivering products that meet the highest standards of quality and performance. The new stainless steel coil is no exception, as it undergoes rigorous quality control processes to ensure that it meets all relevant industry standards and specifications. This commitment to quality is reflected in the company's ISO 9001 certification, which demonstrates its dedication to continuous improvement and customer satisfaction.With a focus on sustainability, {Company Name} also ensures that its stainless steel coil is manufactured in an environmentally responsible manner. The company adheres to strict environmental regulations and implements sustainable practices throughout its manufacturing processes. As a result, customers can be confident that they are choosing a product that is not only high-quality but also environmentally friendly.The launch of the new stainless steel coil is a testament to {Company Name}'s ongoing commitment to innovation and customer satisfaction. By continuously investing in research and development, the company strives to stay ahead of industry trends and provide solutions that meet the evolving needs of its customers. With its extensive experience and expertise in stainless steel production, {Company Name} is well-positioned to deliver a product that sets new standards in the industry.Customers can expect excellent support and service from {Company Name}, as the company's dedicated team is ready to assist with any inquiries and provide technical guidance. Additionally, {Company Name} maintains a robust distribution network, ensuring that its products are readily available to customers around the world.In conclusion, the launch of the new stainless steel coil demonstrates {Company Name}'s commitment to excellence and innovation. With its superior quality, versatility, and sustainable manufacturing practices, the stainless steel coil is set to become a preferred choice for customers across various industries. As {Company Name} continues to lead the way in stainless steel production, customers can look forward to more groundbreaking products that meet their specific needs and exceed their expectations.

High-Quality Roofing Sheet Roll Forming Machine for Sale

[Company Name] is a leading manufacturer of Roofing Sheet Roll Forming Machine in the industry. With a dedication to quality and innovation, the company has been providing high-quality roll forming machines to customers worldwide for many years. Their machines are designed to produce a wide range of roofing sheets with precision and efficiency, making them an essential tool for roofing manufacturers and construction companies.The Roofing Sheet Roll Forming Machine offered by [Company Name] is known for its advanced technology and robust construction. It is designed to roll form different types of roofing sheets with varying profiles and sizes, allowing customers to meet their specific requirements. The machine is equipped with state-of-the-art components and controls, ensuring high productivity and consistent quality in the production process.One of the key features of the Roofing Sheet Roll Forming Machine is its ability to produce roofing sheets with high accuracy and tight tolerances. This ensures that the sheets are uniform in shape and dimension, which is crucial for the installation and performance of the roofing system. Additionally, the machine is capable of producing sheets at high speeds, enabling customers to meet tight production schedules and deadlines.In addition to its performance capabilities, the Roofing Sheet Roll Forming Machine from [Company Name] is also designed with user-friendly features. It is equipped with intuitive controls and easy-to-use interfaces, allowing operators to set up and operate the machine with minimal training. This contributes to increased efficiency and reduced downtime in the production process.Furthermore, [Company Name] provides comprehensive after-sales support for their Roofing Sheet Roll Forming Machine. Their team of technical experts is available to assist customers with installation, training, and troubleshooting, ensuring that the machine operates at its best performance. This commitment to customer satisfaction has contributed to the company's reputation as a reliable partner in the industry.The Roofing Sheet Roll Forming Machine offered by [Company Name] has been widely adopted by roofing manufacturers and construction companies around the world. Its exceptional performance and reliability have made it a preferred choice for businesses looking to enhance their production capabilities and meet the growing demand for high-quality roofing sheets.The company's dedication to innovation and quality has positioned them as a leader in the roll forming machine industry. Their commitment to providing advanced technology and reliable solutions has earned them a strong reputation among their customers and peers.With a focus on continuous improvement and customer satisfaction, [Company Name] continues to push the boundaries of roll forming technology. Their Roofing Sheet Roll Forming Machine is a testament to their expertise and dedication to delivering superior solutions for the roofing industry.In conclusion, the Roofing Sheet Roll Forming Machine from [Company Name] is a testament to their commitment to quality, innovation, and customer satisfaction. With its advanced technology, robust construction, and user-friendly features, the machine has become a trusted tool for roofing manufacturers and construction companies worldwide. As the company continues to lead the industry with their cutting-edge solutions, customers can expect nothing but the best from [Company Name].

Durable and Insulated Sandwich Panel Room for Sale - Find the Best Deals Now

Sandwich Panel Room Brings Innovative Solution for Quick and Efficient ConstructionIn today's rapidly evolving world, the demand for quick and efficient construction solutions is at an all-time high. With the growing population and urbanization, the need for affordable and easily deployable structures has become increasingly important. In response to this demand, (Company Name) has introduced (Product Name), a cutting-edge sandwich panel room that is poised to revolutionize the construction industry.With a focus on sustainability, efficiency, and flexibility, (Company Name) is a leading manufacturer of high-quality construction materials. The company's commitment to innovation and sustainability has led them to develop (Product Name), a state-of-the-art modular construction solution that has garnered attention from industry professionals and customers alike.The unique design of (Product Name) allows for quick and easy assembly, making it an ideal choice for temporary or permanent structures. The sandwich panel construction offers excellent insulation properties, ensuring energy efficiency and comfortable living or working conditions. Not only is (Product Name) easy to install, but it is also durable and can withstand various weather conditions, making it suitable for a wide range of applications.One of the key advantages of (Product Name) is its versatility. Whether it is used for residential, commercial, industrial, or institutional purposes, (Product Name) can be customized to meet specific requirements. The flexibility of the design allows for endless possibilities, from basic single-room structures to multi-story buildings. This adaptability makes (Product Name) an attractive option for developers, contractors, and individuals looking for cost-effective and innovative construction solutions.In addition to its practical benefits, (Product Name) also offers environmental advantages. With a focus on sustainability, (Company Name) ensures that the materials used in the production of (Product Name) are eco-friendly and contribute to a reduced carbon footprint. This commitment to sustainability aligns with the growing global movement towards green construction practices and demonstrates (Company Name)'s dedication to responsible manufacturing.Furthermore, (Product Name) is designed with the end user in mind. The spacious and well-designed interiors provide a comfortable and functional living or working space. The modular nature of (Product Name) allows for easy customization of layouts and configurations, catering to the specific needs of each project. The thoughtfully planned interior spaces, combined with the high-quality construction materials, make (Product Name) a standout choice for modern, efficient, and sustainable construction projects.The introduction of (Product Name) comes at a time when the construction industry is seeking innovative solutions to meet the demands of an ever-changing world. As urbanization continues to grow, the need for affordable, rapidly deployable, and sustainable structures has never been more critical. (Company Name) recognizes this need and is proud to offer (Product Name) as a game-changing solution for the construction industry.With its focus on practicality, sustainability, and versatility, (Product Name) is positioned to make a significant impact in the construction market. By providing a high-quality, efficient, and customizable construction solution, (Company Name) is setting a new standard for the industry. As the demand for innovative and sustainable construction practices continues to rise, (Product Name) stands out as a beacon of progress and a testament to the potential for positive change in the construction sector.In conclusion, (Product Name) is not just a sandwich panel room; it is a testament to (Company Name)'s commitment to innovation, quality, and sustainability. With its focus on practicality, efficiency, and flexibility, (Product Name) is set to redefine the construction industry. As the world continues to evolve, (Company Name) and (Product Name) are at the forefront of driving positive change and shaping the future of construction.

Machine for Making Calamina: The Latest Innovation in Roofing Materials

We are excited to announce the launch of our latest innovation, the Maquina Para Hacer Calamina. As a leading manufacturer in the industrial machinery industry, we have developed this cutting-edge machine to meet the growing demand for high-quality calamina production.The Maquina Para Hacer Calamina is a state-of-the-art piece of equipment that is designed to streamline the process of manufacturing calamina, a type of roofing material commonly used in construction. This machine is equipped with advanced technology and precision engineering to ensure the production of calamina sheets that meet the highest standards of quality and durability.With the Maquina Para Hacer Calamina, our customers can expect increased efficiency and productivity in their calamina manufacturing processes. This machine is capable of producing a wide range of calamina sheet sizes and thicknesses, catering to the diverse needs of our clients in the construction and building materials industry.In addition to its cutting and shaping capabilities, the Maquina Para Hacer Calamina is also equipped with features that ensure the proper coating and finishing of the calamina sheets. This includes the application of protective coatings to enhance the durability and weather resistance of the finished product.Furthermore, our company takes pride in the reliability and user-friendly nature of the Maquina Para Hacer Calamina. We have incorporated intuitive controls and safety features to ensure that operators can work efficiently and safely with this machine. Additionally, our team of technical experts is available to provide comprehensive training and support to our customers to ensure the seamless integration of the Maquina Para Hacer Calamina into their manufacturing processes.As a company committed to innovation and excellence, we have invested significant resources in research and development to bring the Maquina Para Hacer Calamina to the market. We have collaborated with industry experts and leveraged the latest technological advancements to create a machine that sets new standards for calamina production.The launch of the Maquina Para Hacer Calamina represents a significant milestone for our company and reaffirms our position as a leader in the industrial machinery sector. We are confident that this machine will revolutionize the way calamina is manufactured and contribute to the success of our customers in the construction and building materials industry.In conclusion, the Maquina Para Hacer Calamina is a testament to our commitment to delivering innovative solutions that drive the progress of our industry. We are excited about the potential of this machine to transform calamina production and are dedicated to supporting our customers in achieving their manufacturing goals. With the Maquina Para Hacer Calamina, we are proud to offer a reliable, efficient, and cutting-edge solution for the production of high-quality calamina sheets.

High Quality Steel Sandwich Panel for Construction Projects

Steel Sandwich Panel, a leading provider of innovative building materials, has recently introduced a new line of high-quality insulated panels that are revolutionizing the construction industry. These panels are designed to provide superior insulation and structural support, making them an ideal choice for a wide range of building projects.The Steel Sandwich Panel company, established in 1998, has been at the forefront of the construction materials industry for over two decades. With a commitment to quality, innovation, and customer satisfaction, they have built a solid reputation as a trusted supplier of building solutions. Their extensive experience and expertise in the field have enabled them to develop cutting-edge products that meet the evolving needs of the construction market.The newly introduced insulated panels are a testament to the company's dedication to research and development. By utilizing state-of-the-art technology and advanced manufacturing processes, Steel Sandwich Panel has created a product that offers unparalleled performance and durability. The panels are constructed with a core of high-density polyurethane foam, which provides exceptional thermal insulation and soundproofing properties. This innovative design allows for superior energy efficiency and reduced environmental impact, making it an attractive option for eco-conscious builders and property owners.In addition to their outstanding insulation capabilities, Steel Sandwich Panel's insulated panels also boast impressive structural integrity. The steel outer layers provide strength and rigidity, ensuring that the panels can withstand the demands of various building applications. Whether used in walls, roofs, or floors, these panels offer reliable support and protection, contributing to the overall safety and longevity of the structure.One of the key advantages of Steel Sandwich Panel's insulated panels is their versatility. They are suitable for a wide range of building projects, from residential homes to commercial and industrial facilities. The panels can be customized to fit specific size requirements and design specifications, allowing for seamless integration into different architectural styles and construction methods. This adaptability makes them a popular choice among architects, builders, and developers looking for a flexible and efficient building solution.Furthermore, Steel Sandwich Panel is committed to providing comprehensive support to their customers throughout the entire project lifecycle. From initial design consultations to product installation and beyond, their team of experts is readily available to offer guidance and assistance. This unwavering dedication to customer satisfaction sets Steel Sandwich Panel apart as a trusted partner for building professionals seeking reliable and innovative solutions.As the construction industry continues to evolve, the demand for advanced building materials is on the rise. Steel Sandwich Panel's insulated panels are poised to make a significant impact on the market, offering a combination of superior performance, sustainability, and versatility. With their proven track record of excellence and commitment to innovation, Steel Sandwich Panel is well-positioned to shape the future of construction with their groundbreaking insulated panel products.

Top Quality Manufacturer in China for Consumer Goods

China Manufacturer, a leading manufacturer in the industry, has recently made significant advancements in the production of innovative products. With a focus on providing high-quality and reliable products, China Manufacturer has become a preferred choice for customers around the world.Founded in [year], China Manufacturer has quickly grown to become a prominent player in the manufacturing industry. With a state-of-the-art production facility and a team of experienced professionals, the company has built a reputation for delivering top-notch products that meet the highest standards of quality and performance.One of the key factors that sets China Manufacturer apart from its competitors is its dedication to innovation. The company invests heavily in research and development to continuously improve its products and stay ahead of the curve in the industry. By leveraging the latest technologies and manufacturing processes, China Manufacturer is able to produce cutting-edge products that offer superior value to its customers.In addition to its commitment to innovation, China Manufacturer places a strong emphasis on quality control. The company adheres to strict quality management systems to ensure that every product that leaves its facility meets the highest standards of excellence. This attention to detail has earned China Manufacturer a reputation for reliability and consistency, making it a trusted partner for businesses and consumers alike.Furthermore, China Manufacturer places a strong emphasis on sustainability and environmental responsibility. The company recognizes the importance of minimizing its impact on the environment and is dedicated to implementing eco-friendly practices throughout its operations. By adhering to stringent environmental standards, China Manufacturer is able to minimize waste and reduce its carbon footprint, making it an environmentally conscious choice for customers.As part of its ongoing commitment to excellence, China Manufacturer has recently introduced a new line of products that are set to redefine the industry. These products are the result of extensive research and development efforts, and they are designed to offer unparalleled performance, reliability, and value. With a focus on customer satisfaction, China Manufacturer is confident that these new products will meet and exceed the expectations of its customers.In addition to its innovative products, China Manufacturer also offers a range of services to support its customers. From product customization to technical support, the company is dedicated to ensuring that its customers have everything they need to succeed. Whether it's collaborating on custom solutions or providing ongoing assistance, China Manufacturer is committed to delivering exceptional service at every stage of the customer journey.Looking ahead, China Manufacturer is poised to continue its momentum in the industry. The company is constantly exploring new opportunities for growth and expansion, and it is committed to maintaining its position as a leading manufacturer in the market. With a focus on innovation, quality, and customer satisfaction, China Manufacturer is well-positioned to deliver even greater value to its customers in the years to come.In conclusion, China Manufacturer is a standout in the manufacturing industry, with a proven track record of delivering high-quality, innovative products. With a dedication to excellence, sustainability, and customer satisfaction, the company has solidified its position as a preferred choice for businesses and consumers around the world. As China Manufacturer continues to push the boundaries of what's possible, it's clear that the company is set to make even greater strides in the industry.

Expert Tips for Perfecting Roll Forming Dies

Roll Forming Die is an essential component in the manufacturing process of metal profiles and panels. It is a vital tool used in the process of roll forming, which is a continuous bending operation in which a long strip of sheet metal is passed through sets of rolls to gradually form the desired shape. The roll forming die is responsible for shaping and contouring the metal as it passes through the rolls, allowing for the creation of a wide range of products, from simple channels and angles to complex profiles and panels.With the demand for customized metal products on the rise, the roll forming die has become increasingly important in the manufacturing industry. Companies are constantly seeking ways to improve the efficiency and accuracy of their roll forming process in order to meet the demands of their customers. This is where the roll forming die comes into play, offering a precise and reliable solution for shaping and forming metal profiles and panels.One company that has been a leader in the roll forming die industry is {}. With over 30 years of experience in roll forming technology, they have established themselves as a trusted provider of high-quality roll forming dies for a wide range of applications. Their expertise in engineering and designing roll forming dies has allowed them to create innovative solutions that meet the unique needs of their customers.As a leading manufacturer of roll forming dies, {} understands the importance of precision and accuracy in the roll forming process. Their team of skilled engineers and technicians work closely with their customers to design and develop roll forming dies that are tailored to their specific requirements. By utilizing advanced manufacturing techniques and state-of-the-art equipment, they are able to produce roll forming dies that deliver exceptional performance and reliability.In addition to their expertise in roll forming die manufacturing, {} also offers comprehensive support and services to their customers. From initial concept and design to installation and training, their team provides a full range of services to ensure that their customers are able to maximize the performance of their roll forming dies. This commitment to customer satisfaction has helped {} establish long-lasting relationships with their clients and solidify their reputation as a reliable partner in the roll forming industry.In response to the increasing demand for roll forming dies, {} has continued to invest in research and development to enhance their product offerings. They have made significant advancements in the design and production of roll forming dies, incorporating the latest technologies and materials to improve performance and durability. This ongoing commitment to innovation has allowed {} to stay ahead of the competition and remain at the forefront of the roll forming die industry.With the continued growth of the manufacturing industry and the rising demand for customized metal products, the roll forming die has become an indispensable tool for companies looking to stay competitive in the market. As a leading provider of high-quality roll forming dies, {} is well-positioned to meet the needs of their customers and continue to drive innovation in the industry. Their dedication to delivering superior products and services has cemented their status as a trusted partner for companies seeking reliable and efficient roll forming solutions.