Guide to Color Coated Steel Coil: Properties, Applications, and Benefits

By:Admin

In recent years, the construction industry has been witnessing a significant shift towards more sustainable and durable building materials. This trend has led to an increased demand for high-quality products that not only offer superior performance but also contribute to the overall environmental sustainability of a construction project. In response to this growing demand, {Company Name} has introduced its innovative Color Coated Steel Coil, setting a new standard for excellence in the industry.

{Company Name} is a renowned leader in the production and supply of advanced building materials, delivering cutting-edge solutions to meet the evolving needs of the construction sector. The company's commitment to innovation and sustainability has positioned it as a trusted partner for architects, engineers, contractors, and developers worldwide. With a strong focus on research and development, {Company Name} has continuously invested in advancing its product offerings to deliver the highest quality materials for modern construction projects.

The Color Coated Steel Coil is the latest addition to {Company Name}'s extensive range of building materials, designed to offer exceptional performance and aesthetic appeal. This innovative product is manufactured using state-of-the-art technology and high-quality raw materials, ensuring unparalleled durability and longevity. The coil is coated with a special layer of paint that not only enhances its visual appeal but also provides superior protection against corrosion, weathering, and other environmental factors. This makes it an ideal choice for a wide range of applications, including roofing, cladding, and structural components.

One of the key features of the Color Coated Steel Coil is its versatility, as it can be customized to meet specific project requirements. With a wide selection of colors, textures, and finishes available, architects and designers have the freedom to create stunning and unique architectural designs. Furthermore, the coil's excellent formability and flexibility allow for easy installation, reducing time and labor costs for construction projects. This makes it a cost-effective solution for both small-scale and large-scale developments.

In addition to its exceptional performance and aesthetic qualities, the Color Coated Steel Coil also aligns with {Company Name}'s commitment to sustainability. The product is manufactured using eco-friendly processes and materials, minimizing its environmental impact throughout its lifecycle. This includes the use of recycled steel and energy-efficient production methods, further contributing to the overall sustainability of construction projects.

{Company Name} is dedicated to ensuring the highest level of quality and reliability in all its products, and the Color Coated Steel Coil is no exception. Each coil undergoes rigorous testing and quality control measures to meet international standards and certifications, guaranteeing its performance and longevity. This commitment to excellence has earned {Company Name} a solid reputation as a leading provider of premium building materials.

The introduction of the Color Coated Steel Coil represents a significant milestone for {Company Name} and the construction industry as a whole. With its superior performance, aesthetic appeal, and sustainability, the coil is poised to become the new standard in construction innovation. As the demand for more resilient and eco-friendly building materials continues to grow, {Company Name} remains at the forefront, delivering innovative solutions that meet the evolving needs of the market.

In conclusion, the Color Coated Steel Coil by {Company Name} is a game-changer in the construction industry, offering unparalleled performance, aesthetic appeal, and sustainability. With its advanced technology, versatility, and commitment to quality, this innovative product sets a new standard for excellence in building materials. As construction projects continue to prioritize durability and environmental responsibility, the Color Coated Steel Coil emerges as the ideal choice for architects, contractors, and developers seeking top-tier solutions for their projects.

Company News & Blog

Eco-Friendly and Energy-Efficient Sandwich Panel Made of Eps Cement

Eps Cement Sandwich Panel, a Revolutionary Building MaterialEps Cement Sandwich Panel is a revolutionary building material that is gaining popularity in the construction industry due to its numerous benefits and applications. These panels are made from a combination of cement, expanded polystyrene (EPS) foam, and other additives, which are then sandwiched between two layers of non-structural board. The result is a lightweight yet incredibly strong and durable panel that is ideal for use in a wide range of construction projects.The panels are available in various sizes and thicknesses, making them suitable for both interior and exterior applications. They can be used for walls, roofs, and floors, as well as for partition walls and decorative elements. The versatility of Eps Cement Sandwich Panel makes it a popular choice for residential, commercial, and industrial construction projects.One of the key benefits of Eps Cement Sandwich Panel is its excellent thermal insulation properties. The EPS foam core provides a high level of insulation, which helps to regulate the temperature inside buildings and reduce energy consumption. This makes the panels an ideal choice for sustainable and energy-efficient construction.In addition to its thermal insulation properties, Eps Cement Sandwich Panel also offers excellent sound insulation, fire resistance, and resistance to moisture and pests. This makes it a highly versatile and cost-effective building material that is suitable for use in a variety of climates and environments.The company {} has been at the forefront of promoting and supplying Eps Cement Sandwich Panel to the construction industry. With a strong focus on research and development, they have been able to produce high-quality panels that meet the highest standards of performance and durability. Their panels are manufactured using state-of-the-art technology and undergo rigorous quality control processes to ensure consistent and reliable performance.In addition to supplying Eps Cement Sandwich Panel, the company also provides technical support and expertise to architects, engineers, and contractors to help them incorporate the panels into their building designs. They offer comprehensive training and resources to ensure that the panels are installed correctly and that the full potential of this innovative building material is realized.The use of Eps Cement Sandwich Panel is expected to continue to grow as the construction industry seeks sustainable and energy-efficient solutions. With its numerous benefits and applications, this revolutionary building material is likely to become an integral part of modern construction practices.In conclusion, Eps Cement Sandwich Panel is a revolutionary building material that offers a wide range of benefits and applications. Its excellent thermal and sound insulation properties, fire resistance, and resistance to moisture and pests make it an ideal choice for sustainable and energy-efficient construction. With the support and expertise of companies like {}, the use of Eps Cement Sandwich Panel is expected to continue to grow, revolutionizing the way buildings are constructed.

High-quality Roofing Tile Making Machine for Efficient Production

Roofing Tile Making Machine Revolutionizes the Industry with Innovative Features{Company Name}, a leading provider of industrial machinery, has recently introduced a new Roofing Tile Making Machine that is set to revolutionize the roofing industry. This state-of-the-art machine is designed to produce high-quality roofing tiles with superior durability and precision, meeting the growing demands of the construction market.The new Roofing Tile Making Machine features advanced technology and innovative engineering, making it a game-changer in the industry. Its automated operation streamlines the production process, increasing efficiency and reducing labor costs for manufacturers. The machine is also equipped with cutting-edge software that allows for customization and flexibility in tile design, giving manufacturers the ability to meet the diverse needs of their customers.In addition to its technological advancements, the Roofing Tile Making Machine boasts a robust and durable construction, ensuring long-term performance and reliability. Its heavy-duty components and high-quality materials make it capable of withstanding the rigors of continuous operation, delivering consistent and high-quality roofing tiles with every production cycle.Furthermore, the machine is designed with user-friendliness in mind, featuring intuitive controls and a user-friendly interface that make it easy for operators to monitor and manage the production process. This not only enhances productivity but also minimizes the need for extensive training, allowing manufacturers to quickly integrate the machine into their operations and start reaping its benefits.{Company Name} is known for its commitment to innovation and excellence in the industrial machinery industry. With a strong focus on research and development, the company continuously invests in new technologies and engineering solutions to deliver cutting-edge products that meet the evolving needs of its customers.The introduction of the Roofing Tile Making Machine is a testament to {Company Name}'s dedication to driving industry innovation. By leveraging its expertise in engineering and manufacturing, the company has developed a machine that not only meets the current demands of the roofing market but also sets a new standard for quality, efficiency, and reliability."We are excited to unveil our new Roofing Tile Making Machine, which represents a significant leap forward in the industry," said {Spokesperson}, {Title} at {Company Name}. "This machine is the culmination of years of research and development, and we are confident that it will provide our customers with a competitive edge in the market. We are committed to empowering manufacturers with the tools they need to thrive and succeed, and this new machine is a testament to that commitment."As the construction industry continues to grow and evolve, the demand for high-quality roofing materials is on the rise. Manufacturers are under pressure to deliver durable, reliable, and aesthetically pleasing roofing tiles to meet the needs of builders, architects, and homeowners. The new Roofing Tile Making Machine from {Company Name} is poised to address these challenges, providing manufacturers with a powerful tool to enhance their production capabilities and deliver exceptional products to the market.With its innovative features, advanced technology, and robust construction, the Roofing Tile Making Machine is set to make a significant impact on the roofing industry. {Company Name} remains at the forefront of industry innovation, and its commitment to delivering cutting-edge solutions continues to position it as a leader in the industrial machinery market.

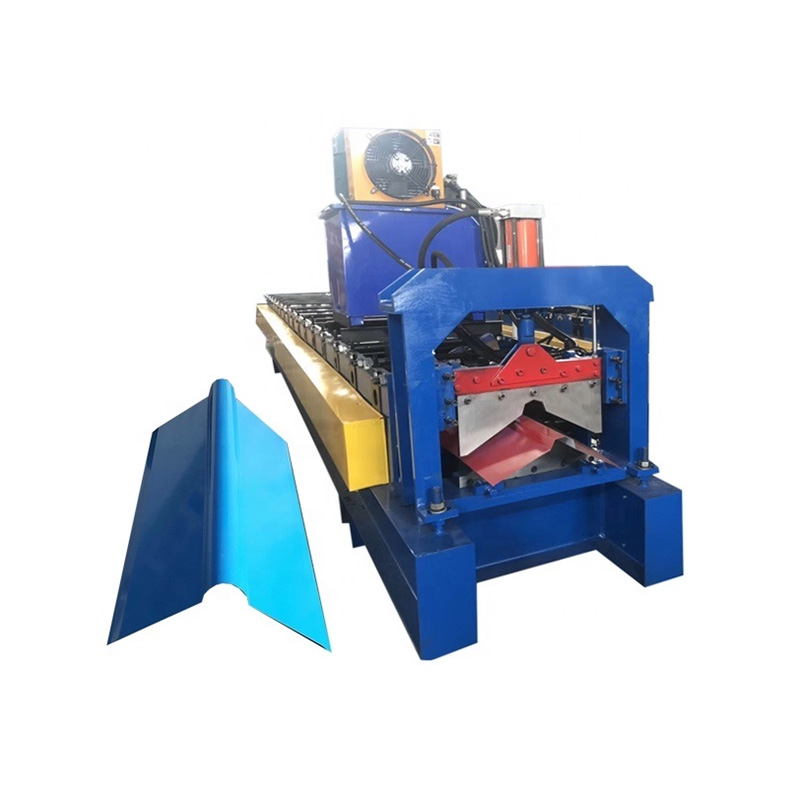

High-Quality Cold Roll Forming Machine for Efficient Production

Cold Roll Forming Machine: Revolutionizing the Metal IndustryIn recent years, the demand for metal products has been on the rise due to the growing construction and manufacturing sectors. As a result, the need for efficient and reliable machinery for metal processing has become increasingly important. This is where the Cold Roll Forming Machine comes into play.The Cold Roll Forming Machine, also known as {Brand Name}, is a cutting-edge piece of equipment that is revolutionizing the metal industry. It is a highly versatile machine that is capable of producing a wide range of metal products with accuracy and efficiency. From simple metal sheets to complex profiles, this machine can handle it all with ease.{Brand Name} is a leading manufacturer of Cold Roll Forming Machines and has been at the forefront of the industry for many years. Their machines are known for their high quality, precision engineering, and reliability, making them the preferred choice for metal processing companies around the world.With a strong focus on research and development, {Brand Name} has continuously improved and innovated their Cold Roll Forming Machines to meet the evolving needs of the industry. Their machines are equipped with the latest technology and advanced features, allowing for seamless operation and superior performance.One of the key advantages of the Cold Roll Forming Machine is its ability to produce metal products with consistent quality and accuracy. This is made possible by the precise control of the forming process, which ensures that each product meets the required specifications. As a result, companies can expect minimal wastage and higher productivity, leading to significant cost savings in the long run.Another notable feature of the Cold Roll Forming Machine is its flexibility. It is capable of producing a wide variety of metal products, including steel frames, roofing panels, wall cladding, and many more. This flexibility allows companies to diversify their product offerings and cater to a broader market, ultimately driving business growth and profitability.In addition to its exceptional performance, the Cold Roll Forming Machine is also designed with user convenience in mind. It features an intuitive interface and user-friendly controls, making it easy for operators to set up and operate the machine with minimal training. This, in turn, leads to improved efficiency and reduced downtime, further enhancing the overall productivity of the manufacturing process.{Brand Name} takes great pride in providing excellent customer support and after-sales service. Their team of experienced technicians is dedicated to ensuring that their customers' Cold Roll Forming Machines are always operating at peak performance. This commitment to customer satisfaction has earned {Brand Name} a strong reputation in the industry and has helped them build long-lasting relationships with their clients.As the demand for metal products continues to grow, the Cold Roll Forming Machine has become an indispensable asset for metal processing companies. Its ability to produce high-quality metal products with precision and efficiency has set a new standard in the industry. With {Brand Name} leading the way with their state-of-the-art machines, the future of metal manufacturing looks brighter than ever.In conclusion, the Cold Roll Forming Machine has significantly transformed the metal industry, providing companies with the capability to produce a wide range of high-quality metal products with precision and efficiency. {Brand Name} has been at the forefront of this revolution, providing top-of-the-line machines and unparalleled support to meet the evolving needs of the industry. As the demand for metal products continues to rise, the Cold Roll Forming Machine is poised to play a vital role in shaping the future of metal manufacturing.

High-Quality Metal Roof Forming Machine for Efficient Roofing

In today's rapidly evolving construction industry, the demand for efficient and reliable metal roof forming machines is higher than ever before. One company leading the way in this field is {}, a reputable manufacturer of state-of-the-art machinery for the production of high-quality metal roofing products. With a strong focus on innovation and customer satisfaction, {} has established itself as a trusted provider of advanced solutions for the construction and metalworking sectors.The metal roof forming machine offered by {} is a testament to the company's commitment to excellence and technological advancement. This cutting-edge equipment is designed to streamline the manufacturing process of metal roofing panels, ensuring precision and consistency in every product. With its high-speed production capabilities and user-friendly interface, this machine enables businesses to meet the growing demand for durable and aesthetically pleasing metal roofing solutions.One of the key features of {}'s metal roof forming machine is its versatility. Whether it's standing seam panels, corrugated sheets, or custom profiles, this equipment is capable of producing a wide range of metal roofing products to meet diverse project requirements. In addition, the machine's innovative design allows for quick and easy tooling changes, minimizing downtime and maximizing productivity for manufacturers.In line with its dedication to customer satisfaction, {} provides comprehensive support and training for customers who invest in its metal roof forming machine. From installation and commissioning to ongoing maintenance and troubleshooting, the company's team of experts is committed to ensuring that clients derive the utmost value from their investment. Furthermore, {}'s commitment to quality extends to the materials used in the construction of its machines, guaranteeing durability and longevity in even the most demanding production environments.The success of {}'s metal roof forming machine can be attributed to the company's extensive industry experience and dedication to research and development. By staying abreast of the latest technological advancements and market trends, {} continues to refine and enhance its machinery to meet the evolving needs of the construction industry. As a result, customers can expect cutting-edge solutions that empower them to stay competitive and achieve excellence in their metal roofing operations.Beyond its commitment to technological innovation, {} is also renowned for its emphasis on sustainability and environmental responsibility. The company's metal roof forming machine is engineered to optimize material usage and minimize waste, aligning with the growing demand for eco-friendly practices in the construction industry. By investing in {}'s machinery, businesses can contribute to a more sustainable future while benefiting from efficient and cost-effective metal roofing production.As the construction industry continues to embrace the benefits of metal roofing, the demand for advanced manufacturing solutions is set to rise. In this dynamic landscape, {} stands out as a trusted partner for businesses seeking reliable, high-performance metal roof forming machines. Backed by a legacy of excellence and a forward-looking approach to innovation, {} is poised to continue driving the industry forward with its cutting-edge solutions.In conclusion, the metal roof forming machine offered by {} represents a pinnacle of engineering and innovation in the construction and metalworking sectors. With its advanced capabilities, versatile production options, and commitment to customer satisfaction, this machinery is empowering businesses to meet the growing demand for high-quality metal roofing products. As the industry evolves, {} remains at the forefront, shaping the future of metal roof manufacturing with its unwavering dedication to excellence.

Metal Roof Tile Making Machine for Stone Coated Roofing

Stone Coated Metal Roof Tile Making Machine Helps Boost Production Efficiency and QualityThe roofing industry is constantly evolving, and with the advancement of technology, new tools and machinery are being developed to meet the growing demand for durable and high-quality roofing materials. One such innovation is the Stone Coated Metal Roof Tile Making Machine, which has been introduced by a leading manufacturing company in the roofing industry.The Stone Coated Metal Roof Tile Making Machine is designed to streamline the production process of stone-coated metal roof tiles, allowing manufacturers to increase their production efficiency and quality. This state-of-the-art machine is equipped with advanced features and technology, making it an ideal choice for roofing manufacturers who are looking to enhance their capabilities and meet the rising demand for high-performance roofing materials.The Stone Coated Metal Roof Tile Making Machine is capable of producing a wide range of stone-coated metal roof tiles in different shapes, sizes, and colors, providing manufacturers with the flexibility to cater to diverse customer preferences. The machine's automated operation and precision engineering ensure consistent and uniform tile production, resulting in high-quality roofing products that are built to last.In addition to its production capabilities, the Stone Coated Metal Roof Tile Making Machine also offers energy-efficient operation, reducing manufacturing costs and environmental impact. This feature makes it an attractive investment for roofing manufacturers who are keen on adopting sustainable and cost-effective production practices.The introduction of the Stone Coated Metal Roof Tile Making Machine is a testament to the company's commitment to innovation and excellence in the roofing industry. With decades of experience and a track record of delivering top-notch roofing solutions, the company has established itself as a trusted partner for manufacturers and contractors nationwide.The company's dedication to research and development has led to the creation of cutting-edge machinery and roofing materials that are revolutionizing the industry. The Stone Coated Metal Roof Tile Making Machine is the latest addition to the company's portfolio of advanced manufacturing equipment, and it is set to make a significant impact on the way stone-coated metal roof tiles are produced.Not only does the machine offer superior performance and efficiency, but it also represents a shift towards sustainable and environmentally friendly manufacturing processes. By investing in this innovative machinery, roofing manufacturers can position themselves as leaders in the industry, offering high-quality, eco-friendly roofing solutions that meet the needs of modern consumers and construction projects.As the demand for durable and aesthetically pleasing roofing materials continues to rise, the Stone Coated Metal Roof Tile Making Machine is poised to play a pivotal role in shaping the future of the roofing industry. Its ability to boost production efficiency, improve quality, and reduce environmental impact makes it a valuable asset for manufacturers looking to stay ahead of the competition and meet the evolving demands of the market.In conclusion, the introduction of the Stone Coated Metal Roof Tile Making Machine is a game-changer for the roofing industry, offering manufacturers a powerful tool to enhance their production capabilities and meet the growing demand for high-performance roofing materials. With its advanced features, energy-efficient operation, and focus on quality and sustainability, this innovative machine is set to revolutionize the way stone-coated metal roof tiles are manufactured, setting a new standard for excellence in the roofing industry.

Benefits of Light Gauge Steel Construction for Your Next Project

Light Gauge Steel Construction continues to gain popularity in the construction industry due to its numerous benefits, including strength, durability, and sustainability. As a leading provider of light gauge steel construction solutions, {}, has been at the forefront of this revolution, offering innovative and high-quality products to meet the growing demand for this construction method.{}Founded in 1998, {} has established itself as a pioneer in the light gauge steel construction industry, with a focus on delivering cutting-edge solutions to its clients. The company's commitment to innovation and excellence has led to its rapid growth and expansion, making it a trusted partner for construction projects of all sizes and complexities.One of the key advantages of light gauge steel construction is its superior strength and durability. Compared to traditional construction materials, light gauge steel offers a higher strength-to-weight ratio, making it an ideal choice for high-rise buildings, commercial structures, and residential homes. Additionally, light gauge steel is resistant to fire, mold, and pests, ensuring a longer lifespan and lower maintenance costs for the building owners.In addition to its strength and durability, light gauge steel construction is also more sustainable and environmentally friendly than traditional construction methods. {} is committed to sustainability and has developed innovative techniques to minimize waste and maximize the use of recyclable materials in its construction projects. By choosing light gauge steel, developers and builders can reduce their environmental impact and contribute to a more sustainable future.Furthermore, light gauge steel construction offers significant cost savings compared to traditional construction methods. The speed and efficiency of the construction process reduce labor costs and shorten project timelines, allowing developers to see a faster return on their investment. Additionally, the lightweight nature of steel components reduces transportation costs and makes the construction process more efficient and cost-effective.As the demand for light gauge steel construction continues to grow, {} has remained at the forefront of the industry, continually developing new technologies and solutions to meet the evolving needs of its clients. The company's team of experts works closely with clients to design and implement customized solutions that maximize the benefits of light gauge steel construction for each unique project.In addition to its technical expertise, {} is also known for its commitment to customer satisfaction and service excellence. The company's dedicated team of professionals is available to provide comprehensive support and guidance throughout the entire construction process, from design and planning to installation and beyond. With a focus on collaboration and communication, {} ensures that each project is completed to the highest standards and meets the specific requirements of its clients.Looking ahead, {} is poised to continue leading the way in the light gauge steel construction industry, with a strong focus on innovation, sustainability, and customer satisfaction. As the construction industry embraces the numerous benefits of light gauge steel, {} remains committed to delivering the highest quality products and solutions to meet the evolving needs of its clients.In conclusion, light gauge steel construction has become a game-changer in the construction industry, offering unparalleled strength, durability, sustainability, and cost savings. As a leading provider of light gauge steel construction solutions, {} has demonstrated its commitment to excellence and innovation, making it a trusted partner for construction projects of all types. With a focus on customer satisfaction and service excellence, {} continues to set the standard for light gauge steel construction and is poised to shape the future of the industry for years to come.

High-Quality Roofing Sheet Making Machine for Efficient Production

Roofing Sheet Making Machine Revolutionizing the Construction IndustryThe construction industry is constantly evolving with new technologies and innovations to improve efficiency and quality. One such innovation that is making waves in the industry is the Roofing Sheet Making Machine, a cutting-edge piece of equipment that is revolutionizing the way roofing sheets are manufactured.The Roofing Sheet Making Machine is a state-of-the-art technology that is designed to automate the process of producing roofing sheets. This machine has the capability to produce high-quality roofing sheets with precision and speed, significantly reducing the time and labor required for traditional manufacturing methods.With the Roofing Sheet Making Machine, manufacturers can now produce roofing sheets in various designs, sizes, and materials to meet the diverse needs of the construction industry. This flexibility allows for greater customization and innovation in roofing design, leading to more aesthetically pleasing and functional roofing solutions for buildings.The machine is equipped with advanced features such as automated material feeding, roll forming, cutting, and stacking, all of which are controlled by a user-friendly interface. This level of automation ensures consistent and accurate production, reducing the margin of error and minimizing material wastage.In addition to its efficiency, the Roofing Sheet Making Machine is also environmentally friendly. By optimizing material usage and reducing waste, it contributes to sustainable manufacturing practices, which are increasingly important in the construction industry.One company that has been at the forefront of introducing the Roofing Sheet Making Machine to the market is {}. With years of experience in the manufacturing and supply of construction machinery, {} has established itself as a leading provider of innovative solutions for the construction industry.{}'s Roofing Sheet Making Machine is a result of extensive research and development, aimed at addressing the challenges faced by traditional roofing sheet manufacturing processes. The company has leveraged its expertise in engineering and technology to create a machine that sets new standards for reliability, efficiency, and quality in the production of roofing sheets.The company's commitment to customer satisfaction and after-sales support has ensured that the Roofing Sheet Making Machine is not only a cutting-edge technology but also a reliable and cost-effective solution for manufacturers. With a comprehensive service network and technical expertise, {} has become a trusted partner for businesses looking to invest in advanced manufacturing equipment.As the demand for innovative and sustainable construction solutions continues to grow, the Roofing Sheet Making Machine is set to play a key role in shaping the future of the industry. By streamlining the production process and improving the quality of roofing sheets, this technology is poised to have a significant impact on the efficiency and aesthetics of buildings worldwide.In conclusion, the Roofing Sheet Making Machine represents a major advancement in the construction industry, offering a combination of efficiency, quality, and sustainability that is unparalleled by traditional manufacturing methods. With companies like {} leading the way in bringing this technology to market, the future of roofing sheet production looks brighter than ever.

Discover the Benefits of Lightweight Steel Frame Construction

[Company Name], a leading construction and manufacturing company, is revolutionizing the industry with its innovative Lightweight Steel Frame technology. This cutting-edge construction solution offers unparalleled strength and durability while significantly reducing building costs and construction time.The Lightweight Steel Frame is a game-changer in the construction industry, offering a sustainable and cost-effective alternative to traditional building materials. This technology is the result of years of research and development, and [Company Name] has successfully implemented it in various construction projects, delivering exceptional results every time.Unlike traditional building materials, the Lightweight Steel Frame is incredibly durable and resistant to rust and corrosion. This means that structures built with this technology are more robust and have a longer lifespan, making it a highly sustainable and environmentally friendly choice for construction projects.In addition to its durability, the Lightweight Steel Frame is also significantly lighter than conventional building materials, which translates to lower transportation and installation costs. This lightweight nature also makes it easier and faster to construct buildings, reducing construction time and labor costs.Furthermore, the versatility of the Lightweight Steel Frame allows for innovative and unique architectural designs. Whether it's a residential, commercial, or industrial project, [Company Name] can customize the Lightweight Steel Frame to meet specific design requirements, giving architects and developers the freedom to create stunning and practical structures.One of the key advantages of the Lightweight Steel Frame is its ability to withstand extreme weather conditions, making it ideal for a wide range of applications. From earthquake-prone areas to regions with harsh climates, structures built with this technology offer superior resilience and safety, making them an ideal choice for construction projects in challenging environments.[Company Name] is committed to delivering high-quality and sustainable construction solutions, and the Lightweight Steel Frame is a testament to this dedication. The company's team of experts works closely with clients to understand their unique needs and requirements, providing tailored solutions that maximize the benefits of this innovative technology.The Lightweight Steel Frame technology has already been successfully implemented in a wide range of construction projects, including residential housing, office buildings, and industrial facilities. These projects have not only demonstrated the exceptional strength and durability of the Lightweight Steel Frame but also the significant cost and time savings it offers.In a statement, the CEO of [Company Name] expressed their enthusiasm for the impact the Lightweight Steel Frame technology is having on the construction industry. "We are proud to be at the forefront of innovation in the construction and manufacturing sector. The Lightweight Steel Frame technology is a game-changer that is redefining the way buildings are constructed, offering unmatched strength, durability, and sustainability," the CEO said.The company's commitment to continuous improvement and innovation has positioned them as a leader in the industry, and the Lightweight Steel Frame is a testament to their expertise and dedication to delivering cutting-edge construction solutions.As the demand for sustainable and cost-effective construction solutions continues to grow, the Lightweight Steel Frame is set to play a crucial role in shaping the future of the industry. With its exceptional strength, durability, and versatility, this technology is poised to become the go-to choice for developers and architects looking to create resilient and sustainable structures.[Company Name] is dedicated to driving the adoption of the Lightweight Steel Frame technology and is actively working with industry partners and stakeholders to promote its benefits and applications. As the construction industry continues to evolve, [Company Name] is well-positioned to lead the way with its innovative Lightweight Steel Frame technology, setting new standards for sustainable and efficient construction practices.

Top Steel Framing Machines for Your Construction Needs

Steel Framing Machines: Revolutionizing the Construction IndustryThe construction industry plays a crucial role in the development of infrastructure around the world. With the continuous evolution of technology, new methods and materials are constantly being innovated to enhance the efficiency and quality of construction processes. One such innovation that has gained significant attention is the use of steel framing machines, which have revolutionized the way steel frames are created for buildings and structures.Steel framing machines have become increasingly popular among construction companies and contractors due to their ability to streamline the process of creating steel frames for buildings. These machines are equipped with advanced technology and automation features that allow for precise and efficient production of steel frames, ultimately reducing the time and labor required for traditional construction methods.One company that has been at the forefront of this revolutionary technology is {}. The company has established itself as a leading manufacturer of steel framing machines, offering a wide range of innovative solutions for the construction industry. Their state-of-the-art machines are designed to meet the diverse needs of construction projects, from small-scale residential buildings to large-scale commercial and industrial structures.With a strong focus on research and development, {} has continuously refined and enhanced their steel framing machines to ensure optimal performance and reliability. Their machines are engineered to deliver high levels of accuracy and consistency in the production of steel frames, ensuring that the final product meets the highest quality standards.In addition to their cutting-edge technology, {} is committed to providing comprehensive support and service to their customers. They offer training programs and technical assistance to help construction professionals maximize the potential of their steel framing machines, ensuring that they are able to leverage the full benefits of this innovative technology.The impact of steel framing machines in the construction industry has been significant, offering a wide range of benefits that have transformed the way steel frames are produced. One of the key advantages of these machines is their ability to expedite the construction process, allowing for faster project completion and reduced labor costs. With the automation capabilities of steel framing machines, the need for manual labor and time-consuming processes is significantly diminished, resulting in increased productivity and efficiency on construction sites.Furthermore, steel framing machines have proven to be highly versatile, capable of producing steel frames of varying shapes and sizes to accommodate the unique requirements of different construction projects. This flexibility has enabled construction companies to take on a wider range of projects, ultimately expanding their capabilities and opportunities in the industry.Another significant impact of steel framing machines is their contribution to sustainability in construction. Steel is a highly sustainable and recyclable material, making it an environmentally friendly option for building structures. By using steel framing machines to produce steel frames, construction companies are able to reduce waste and minimize the environmental impact of their projects, aligning with the growing emphasis on sustainable construction practices.As the demand for steel framing machines continues to grow, {} remains committed to driving innovation and excellence in the construction industry. Their dedication to advancing the capabilities of steel framing machines has positioned them as a trusted partner for construction professionals seeking to enhance their construction processes and deliver high-quality results.In conclusion, steel framing machines have emerged as a game-changing technology in the construction industry, offering a plethora of benefits that have redefined the way steel frames are produced for buildings and structures. With companies like {} leading the way in the advancement of this technology, the future of construction holds exciting prospects for increased efficiency, sustainability, and quality in building practices.

Modern and efficient light steel frame prefabricated houses

Light Steel Frame Prefabricated House - A Revolution in Modern ConstructionThe construction industry has undergone a significant transformation in recent years, with the emergence of innovative building materials and techniques. One such revolutionary development is the light steel frame prefabricated house, which has gained widespread popularity due to its numerous advantages over traditional construction methods.The concept of light steel frame prefabricated houses involves the use of high-quality steel frames to create modular living spaces that can be easily assembled and disassembled at the desired location. These prefabricated houses are designed to be durable, energy-efficient, and eco-friendly, making them an ideal choice for modern living.One of the leading providers of light steel frame prefabricated houses is a company that has been at the forefront of this innovative construction technology. With a strong focus on research and development, the company has successfully developed a range of prefabricated house designs that meet the highest standards of quality and safety.The key advantage of light steel frame prefabricated houses lies in their quick and easy assembly process. Unlike traditional brick and mortar construction, these prefabricated houses can be set up in a matter of days, significantly reducing construction time and costs. This makes them an attractive option for individuals and businesses looking for efficient and cost-effective housing solutions.In addition to their rapid assembly, light steel frame prefabricated houses offer superior durability and structural integrity. The high-quality steel frames used in their construction provide excellent resistance to external forces such as wind, earthquakes, and fire, making them a safe and reliable housing option for challenging environments.Furthermore, these prefabricated houses are designed to be energy-efficient, with enhanced insulation and ventilation systems that help to reduce heating and cooling costs. This not only benefits the environment but also provides long-term cost savings for homeowners.Another key feature of light steel frame prefabricated houses is their versatility in design and customization. From single-family homes to multi-story buildings, these prefabricated houses can be tailored to suit a wide range of architectural styles and functional requirements. This flexibility allows for creative and innovative solutions in residential and commercial construction projects.Moreover, the use of light steel frame prefabricated houses contributes to sustainability and environmental conservation. The steel frames are recyclable, and the construction process produces minimal waste compared to traditional building methods. This aligns with the growing emphasis on green building practices and sustainable development in the construction industry.With their many benefits, it is no surprise that light steel frame prefabricated houses are becoming increasingly popular in the construction industry. They have been successfully used in various residential, commercial, and industrial projects, offering a modern and efficient solution for the growing demand for high-quality housing.In conclusion, the emergence of light steel frame prefabricated houses represents a significant advancement in modern construction technology. With their quick assembly, durability, energy-efficiency, and versatility, these prefabricated houses are revolutionizing the way we build and live. As the demand for efficient and sustainable housing solutions continues to grow, it is expected that light steel frame prefabricated houses will play a crucial role in shaping the future of the construction industry.